Our services

Design

Our technical staff, supported by our welding engineer, possesses the experience and tools to assist our customers in the design and management of their projects. We are always ready to assist and advise you with innovative solutions, therefore, allowing you to be more efficient in the pursuit of your objectives. We work with the latest 3D modelling and management software in order to optimize our work and exceed our customer's expectations.

- Mechanical design software Autodesk Inventor Pro;

- Drafting software BIM 3D Autodesk Advance Steel;

- Planning & manufacturing software ERP Graitec Advance Workshop;

- Planning and project follow-up with Microsoft Project & Excel.

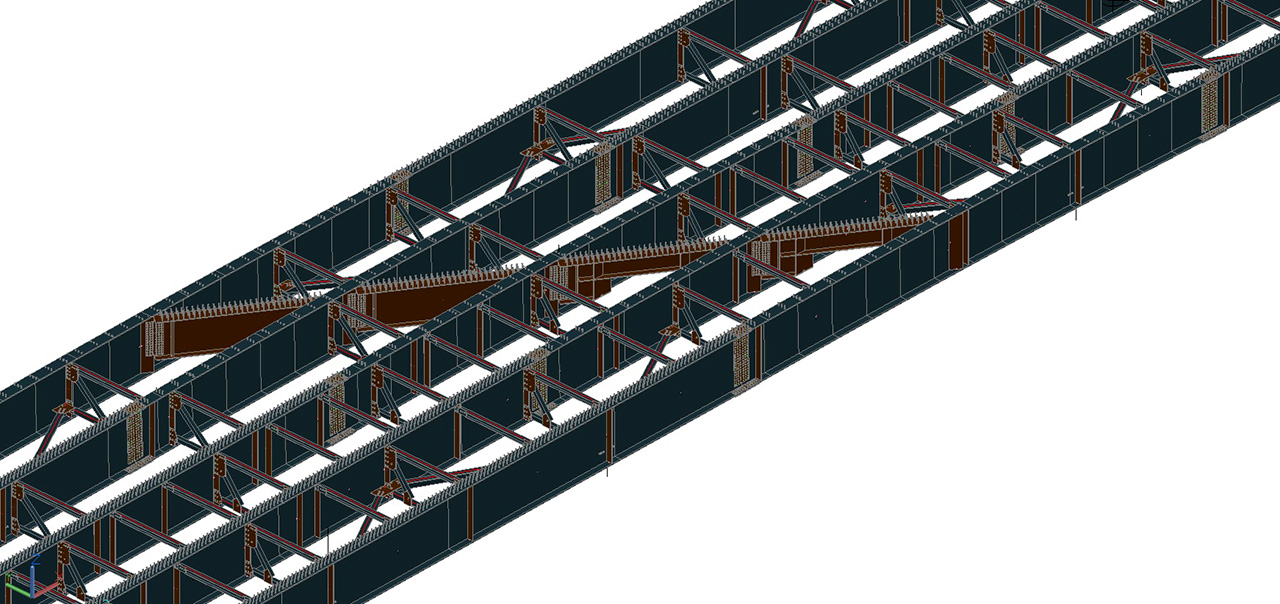

Detailing

Our experienced technicians use BIM 3D modelling software to realize the shop drawings of your project. This software ensures the perfect assembly of steel components on site; in other words, a collision-proof and interference-proof assembly. We are, therefore, a valued partner in the realization of your fast track projects where the rapidity of execution is key. The information files can then be imported directly in our machines from the 3D model, thus considerably reducing fabrication delays and risk of errors associated with manual programming.

- Drafting software BIM 3D Autodesk Advance Steel

Fabrication

For many years now, Pro-Mec Elite's team is renowned for the quality of its deliverables. We are capable of offering products & services within the fastest delays at a competitive price thanks to our modern installation and skilled labour. The precision of components we fabricate allows for bolted or welded assemblies to be easily installed on site. We continually invest in the maintenance and modernization of our equipment as well as in the training of our employees in order to remain at the market forefront in regards to our fabrication service.

Choose a certified company:

- Quality management system certified ISO 9001 :2008;

- Certified under standard CSA W47.1 division 1 by the Canadian Welding Bureau;

- Welding engineer in-house;

- Certified CWB welding inspectors level 1 & 2 in-house.

Machine capacities:

- 2x 15T overhead cranes (30T total lifting capacity)

- Drill Line (automated drilling line) FICEP mod. 1001 DFB with saw

- Oxy-fuel / plasma cutting table Vision 1000 8' x 12'

- FCAW/MCAW welding machine, Lincoln Idealarc DC600 with double feeder

- GTAW welding machine, Lincoln Precision TIG 375

- SAW welding machine, ESAB LAF-1001

- Stud welding machine, SC3400

- Lathe Cy-Drummond dia. 8-1/2 x 60" lg

- Milling Van Norman travel of 29" x 11"

- Saw Hyd-Mech S23A automatic 16"

- Pipe bending machine

- 100T shop press

- Vallée (30 000 lbs), Caterpillar and Hyster lifts

- Western Star truck with 48' flatbed and B-train trailer

Delivery

With the help of our own semi-trailer truck, we are able to deliver your components on site at the precise time you need them. We offer this "just in time" personalized delivery service to all our customers across the province which is non-negligible advantage for a successful project, especially when delivery schedules are tight.